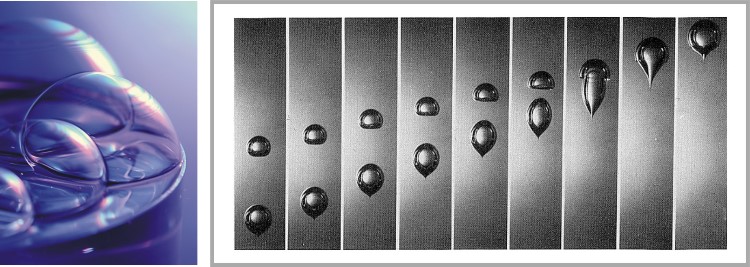

For mixing and dspersing the high viscous materials(100,000 ~1,000,000 mPas), conventional type’s mixers such as stirrer or homogenizer must encounter the barriers for treating them because they are designed for mixing the low viscous materials. On the other hand, while orbiting, turning and rotating upon its axis, the chamber creates the centrifugal forces in a horizontal direction and rotation creates the vector force in a vertical direction. Vector sum is obtained and performed by adding each corresponding vector. The gravity force(G force) for mixing and dispersing which is drawn from equation with these vectors and high viscos materials are mixed and dispersed perfectly in a short period of time. Centrifugal force also gives good advantageous point for defoaming inside the samples which must be prevented against the oxidation, diffusion, air dispension and denaturation.

Introduction of paste mixer series

Inside the PDM-1KV

The Tool for Mixing & Dispersing

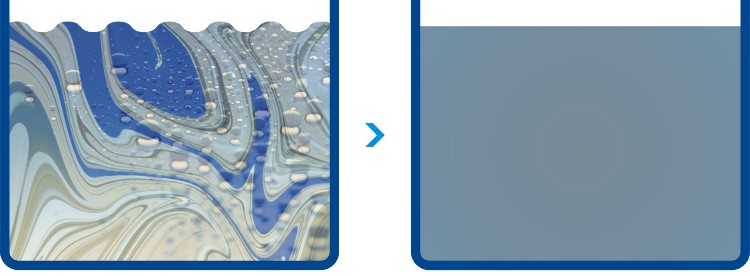

The core technology of paste mixer is designated by the performance of perfect mixing and dispersing with the vector sum caused by revolution and rotation movement. The centrifugal force in a horizontal direction have the heavy density’s materials moving from up to down. On the other hand, another vector in a vertical direction created by rotation have the heavy density’s materials moving from down to up.This movement repeats continuously inside the sample and this is core origin for mixing and disepersing for high viscous materials.

Defoaming inside the high viscous materials

It’s very difficult to eliminate the bubbles inside the high viscous materials. Centrifugal force also gives good advantageous point for defoaming inside the samples which must be prevented against the oxidation, diffusion, air dispension and denaturation. The way of speed adjustment of revolution and rotation or vacuum pressure are very important for defoaming.

Oxidataion and denaturation of the sample caused by bubbles

PDM-300 Test(Refence. PDM 1KV has same structure and functionality with PDM-300V)

*Max speed : 600 rpm

*Max volume 500 ~700 ml x 2 cups (total 1,000 ~ 1,400 ml)

*Adjustment of each RPM is available withprogrammable buttons (incl. step timer)

*Interal type of vacuum pump (optional)

*Mixing and defoaming in a short time

*High reproducible results

*Prevents materials breakdown and potentialwaste

*Easy cleanup without needing to cleanaccessories such as mixing blades

*Ability to mix materials with differentviscosities and density

*Dispesingnanao paticles to eliminate aggregation

Broad range of industries and in the research and development labs and production facilities for semiconductors, liquid crystrals, paints, pharmaceuticals, cosmetics, food prodcutions, resin and metallic paste