he entire history of adhesives is rather fascinating. Early humankind discovered adhesives and glues found in birch bark and plant gums. They soon discovered they could treat the plant gum with red ochre to create a much stronger bond. The glue was used to help fasten stone to wood in the production of axes and other tools. This history of adhesives is interesting and illustrates why major manufacturing companies like Henkel, Avery, 3M and more have dedicated themselves to the improvement of all manner of adhesives.

The Sonolator high pressure homogenizer is an innovative mixing unit that very effectively emulsifies a wide range of fluids, resins and epoxies in the adhesive manufacturing process. The Sonolator also does an outstanding job of dispersing fumed silica or other solids into polyester resins.

Whether it is the dispersion or dispersion or deagglomeration of solids like fumed silica, often used with polyester resin, or the emulsification of epoxy resins, the homogenization process is key factor in reducing the particle size of glues, epoxies and resins. Smaller particles allow for better surface coverage when applied. The process also tears apart solids agglomerates, eliminating not just larger lumps but micron-sized particulates.

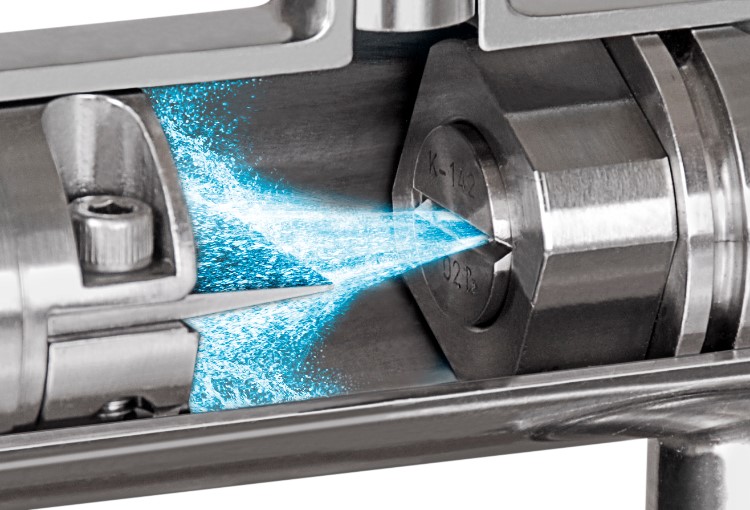

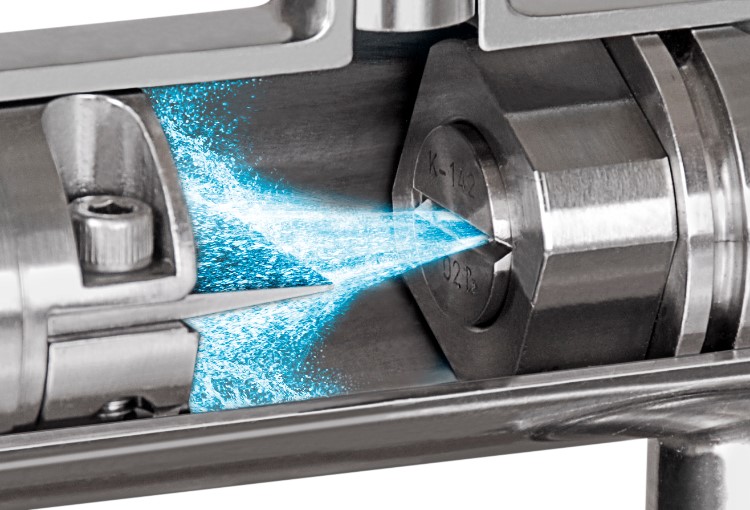

The Sonolator uses a high pressure PD pump operating between 100 and 5,000 PSI to accelerate the fluid over a minute distance. This rapid change in fluid velocity tears apart droplets and particles within the fluid stream. When then force the fluid over a knife-like blade that imparts extreme cavitation within the fluid, reducing particle size even further.