Lithium, or soap-based, greases are white in appearance and are comprised of fatty acids and salts. They tend to be very temperature tolerant, non-corrosive and adhere nicely to metal surfaces.

Polyurea greases are byproducts of resin compounds, amines and isocyanate. This mixture makes for much higher tolerance to heat for longer periods of time, therefore becoming a common choice for bearing manufacturers.

Bentonite grease is manufactured using bentonite clay which imparts excellent sealing properties as well as resistance to softening at higher temperatures.

The soaps in the lithium and aggregates or clays within the polyurea and bentonite need to be properly dispersed within the liquid medium without over-shearing. Any milling equipment needs to handle the high viscosity of these fluid mixtures as well. This is where our colloid mills for grease do a great job!

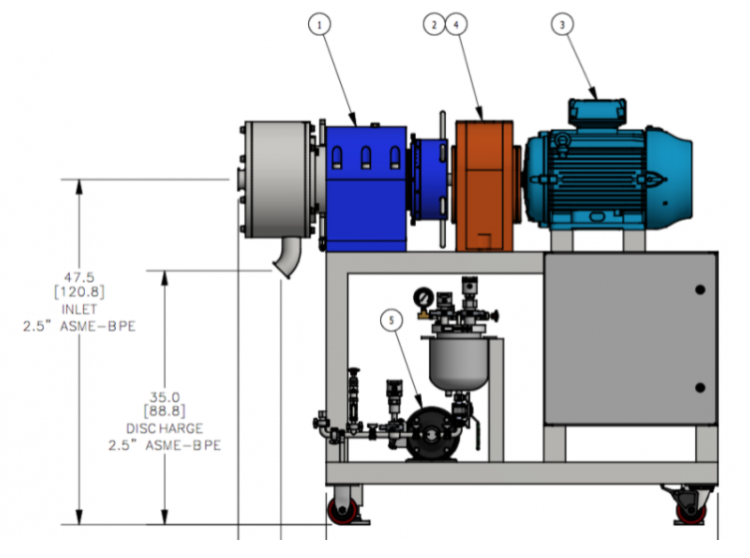

Sonic Corp designs and custom builds production scale Colloid Mills to size 12 inch diameter rotors for processing various greases. Production scale equipment can process up to 1600 GPH using pressure fed inlet. It’s our ability to customize these units into skids with various components that sets us apart from the competition. As you can see, we provide a 3D design for approval that can include any of the following: