In a typical factory setup, an oil phase and a water phase are produced in separate vessels at high temperatures then slowly merged into a single vessel. The mixture is then agitated and cooled over a lengthy time, as much 5-10 hours, until the emulsion is fully formed. This is an inefficient process because:

Many years of innovative process development have led to what we call multiple-feed homogenization where our inline Sonolator device is connected to two or more PD pumps to accurately meter different phases at different temperatures under high pressure to make instant emulsions. It’s extraordinary to see a basic Dual-Feed Homogenizing process where a hot oil phase is metered alongside an ambient water phase at high pressure to instantly form a room temperature emulsion.

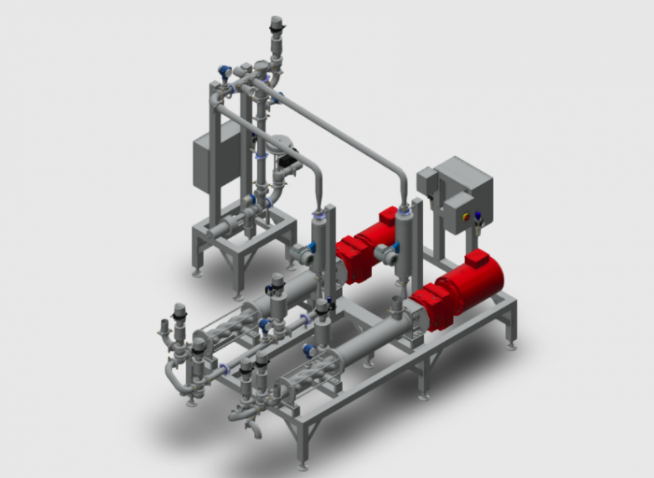

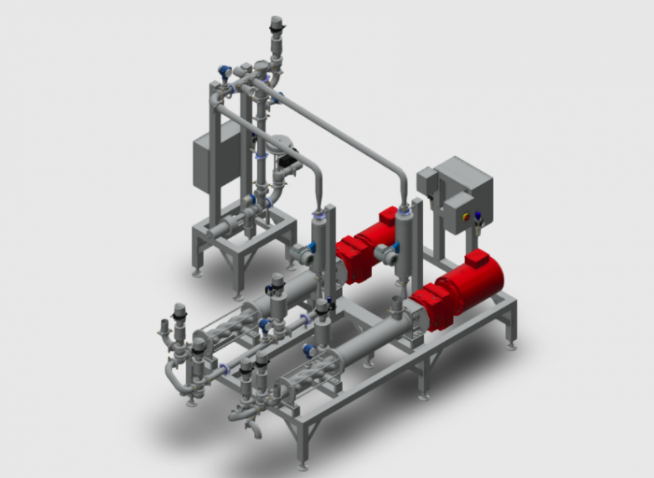

The 3D image here illustrates a system we designed for a large scale lotions manufacturer who wanted to capitalize on the time savings our process approach offered. The skid featured 2 progressive cavity PD pumps operating at 400 psi pressure and delivering a combined flow rate of 50 GPM. The 2 streams were merged into a common pipeline and into the Sonolator mixing chamber where cavitation and shear reduced the oil droplets inline. The system used state of the art PLC controls with mass flow meters to establish accurate metering between the hot oil phase and ambient water stream.

The benefits continue to stack up in this example of processing lotions. Now that we can inline emulsify a hot oil with cooler water phase without merging them to a batch tank, we can reduce the heating time and cost because we are only heating the oil phase, which might only be between 5-20% of total product. So instead of heating a large mixing vessel, we now heat one that is all but 5-20% of that original tank size. When this small percentage oil phase is metered at higher temperature with the cooler water phase, the resulting product is much closer 30-35 degrees C, requiring little to no cooling! Take an extra step and remove a large amount of plain DI water using a third pump and get more finished product from smaller tanks.

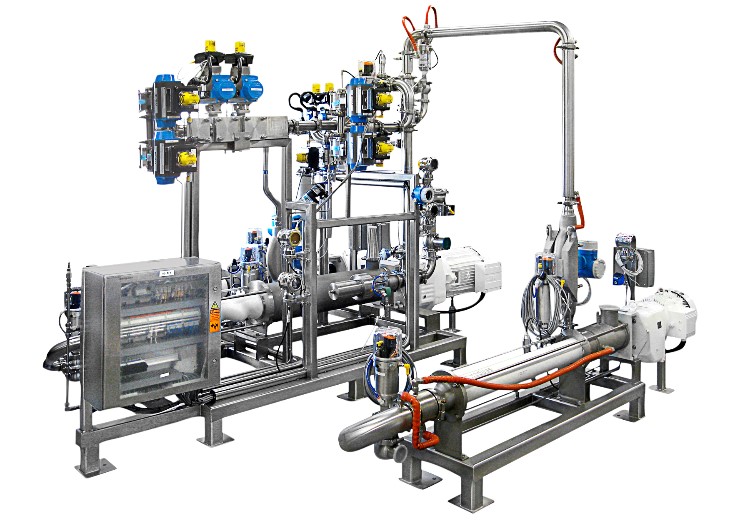

Sonic designs multiple-feed Homogenizing systems for the instant emulsification of hand & body lotions. All the necessary components are chosen and designed into a comprehensive system that will take two or more phases and meter at proper ratio to create instant emulsions. The Sonolator process is highly repeatable and very scalable: